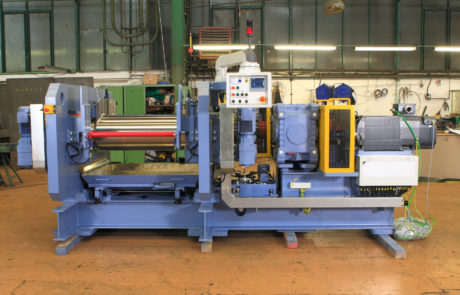

Heavy duty design for any customer application.

Two-roll mills

Many years of experience in this field are used to produce these devices. Full production control gives us a great advantage in this section of engineering. Buzulukhas its own foundry for rolls casting. The rolls from our own castings are fully machined in our machining shop. The surface hardness of the rolls is 500 ± 20 HBr at a depth of 10 – 15 mm. Our own cast iron process guarantees the best quality product.

Under surface drilled cooling channels are standard, but also rolls with cavity cooling are available.

With lower acquisition costs, shorter lead times and minimal maintenance, cavity rolls offer standard applications in many areas. On the other hand, when better temperature control and cooling are required, under surface drilled rolls are a the only alternative.

Main characteristics

Main characteristics

| Machine type | 03879 | 03876 | 03871 | 03856 | 03742 | 03858 | 03836 | 03552 |

03577 (03552) |

|

|---|---|---|---|---|---|---|---|---|---|---|

| Roll diameter | mm | 160 | 200 | 300 | 400 | 460 | 560 | 610 | 650/750 | 750 |

| Typised roll length | mm | 385 | 400 | 700 | 1000 | 1200 | 1500 | 1800 | 2100/800 | 2500 |

|

Typised speed |

m/min | 1,25-12,5 | 1,6-15 | 1-11 | 3,3-33 | 3,3-33 | 3,3-33 | 3,3-33 | 3,3-33 | 3,3-33 |

|

Recommended drive power for single friction ratio |

kW | – | – | 22 | 55 or 75 | 90 | 132 | 150 | 200/300 | 300 |

|

Recommended drive power for variable friction ratio |

kW | 2 × 7,5 | 2 × 7,5 | – | 2 × 45 | 2 × 55 | 2 × 75 | 2 × 90 | 2 × 132 | 2 × 160 |

|

Cooling water consumption |

m3/hour | 5 | 5 | 8 | 12 | 14 | 14 | 15 | 16/9 | 18 |

Remark: Type 03876 is for laboratory use only.

The length of the rolls can be adapted to the customer’s requirements.

Cooling water flow is calculated at the base of the drilled rolls excluding the Stockblender.